Update: Last time we were in mini-ville I had dribbled river rocks on to the luan plywood foundation - looked good until they started falling off. Apparently the foundation warped & when I weighed it down some of the rocks didn't like the change & popped off! Next time I will mix glue into the Water Putty.

I re-did the foundation in a textured finish, in a warm grey & used the 1st porch I made. We decorated this 'facade thing' as a Xmas display for the local hospital & someone actually bought it?!

So I think I'll stay away from decorating for awhile & concentrate on design & construction of dollhouse shells!

New Project

|

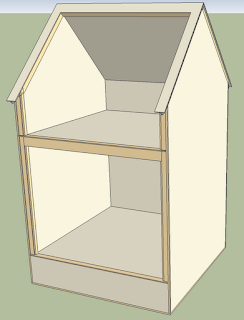

The possibilities are endless...

the kit builder would add their own components: windows, doors, shingles etc., including a porch & a couple of dormers in the above example.

|

I'm going back to my mat board & stick design as the luan plywood is problematic. I'm currently building all the jigs for the connectors I'll need. I liked the sliding dovetail joint but found it difficult to make so I've come up with a simpler design.

The dollhouse is stick built with either 1/16" mat board as the skin. The finished walls are 3/8", but I made the floors 5/8" thick as I thought they needed to be bit more beefy.

My idea is that I build the outer frame & glue the mat board to the exterior. Then the customer or 'kit builder' glues on the precut studs, joists & rafters & with a craft knife cuts out all the openings. This allows total freedom to place doors, windows, skylights, etc. whatever size or style & wherever desired. And two simple hand tools: a craft or utility knife & a razor saw w/miter box.

The walls, floors & roof can be assembled/disassembled in minutes. Also, I think I've come up with an easy way to electrify the dollhouse using a circuit board & computer ribbon cables & connectors. See below:

|

| Ribbon wire plugged into circuit board, other end cut off & attached to wall wiring. |

|

Contact happens between the floor joist &

floor support where the bronze bands are wrapped or pinned?

|

House Rules? This dollhouse building system allows the kit builder to choose the size of the house within the following parameters:

- Rectangular or square floor plan, no pop outs, dormers, etc. Although commercial dormers, bay windows, etc. can be added. And I think I could easily design additions to the gable side(s) using the same system.

- Gable style 'A' roof with a 45° pitch. Most commercial dormers I believe are 45°. I may add 30° & 60° pitch in the future? 30/60 adds gambrel & mansard roofs!

- Maximum interior dimensions: 15-1/2"d x 19-1/2"w x 20-1/8"h. Why these dimensions? Because I'm buying 16" x 20" mat board by the case from Golden State Art - A1 company, good prices & free shipping! What's not to like...

Construction from the ground up:

|

| (4) Base plates |

|

| (8) Corner posts |

|

| (8) Floor supports |

|

| (1) Front roof connector |

|

| (4) Gable end rafters |

|

| (4) Roof end connectors |

|

| Cross members: (2) Ridge connectors & spline; (2) [Back cutout frame; Front eaves frame] |

|

| (8) T-joists & (2) Back sills |

|

| Roof edge trim |

|

| Exterior mat board |

|

| The kit builder adds precut studs. The studs would be positioned around window & door openings. Joists around stairwells & rafters around skylights or chimneys, etc. |

|

Then the kit builder adds the interior mat board.

Obviously someone forgot to cut out the openings for this house - hmmm jail house?

|

|

| Then the interior mat board is glued in place, dried, then the interior mat board is trimmed from the outside using the same method as above. |

Assembled in sections:

|

| Left wall |

|

Place the front wall to the corner connector of the left wall then insert locking spline.

See detail below:

(click to enlarge)

|

|

| Repeat with right wall. |

|

| Slide in floors. |

|

| Lock back to sides with splines. |

|

| Add front roof. |

THE JIGS: Quick change jigs attach to table saw

|

| Jig in position. |

|

| When the strip wood enters the jig I'll use a push stick for the remainder of the cut. |

|

...and the full width of the groove is accomplished. This takes much longer to explain than it does to actually do! Of course I would run a bunch of strip wood through this jig before moving on to the next. Ahhh the assembly line... The wall corner & roof ridge connectors need to be laminated. I use Titebond II wood glue & evenly spaced drops of Gorilla super glue. I weight the parts down for 20 seconds or more - the parts are bonded enough to remove them from the gluing jig - freeing up the gluing jig for the next set of parts. I put the glued parts aside for 24 hours or more.

|

Thinking out loud about what I could do with this system...

- I could use it to quickly build dollhouses to completion for shows, sale, trade, gifts or charity

- Sell custom shells according to the kit builder's specs, with interior framing & cut outs completed & possibly wiring

- Sell shells according to my specs, with interior framing, cut outs, wiring completed

- Sell as a kit - where the kit builder would do the interior framing, cut outs. (wiring components included?)

- Sell the wooden connectors/parts in 24" lengths with a pack of mat board on the side, (wiring components included?)

Quick study or crude beginnings

|

| Floor & wall attached with floor board tucked under baseboard. |

|

| Walls or 45° pitch roof sections. |

|

| Connecting roof halves or walls with locking spline. Spline slides from the top into position. |

|

| Parts locked in place. |

UPDATE

I'm still here - busy building jigs! I've got most of them done...waiting for some basswood I ordered - should be here next week - will start building a dollhouse then...

Imagining

|

| The interior measures 12"W x 8"D |

|

| The 1st floor is set as far down as it will go & there's no knee wall in attic. |

The Jigs

I've condensed the dozen or so jigs into one jig...

__________________________________________________________

Found this great calculator site on compound miters

This is great to calculate an 'L' or 'T' shaped house wing / floor plan.

I'm using the 1st calculator of Chris Glad's:

Slope = the pitch. I'm only using 45°, so I enter 45.

Included Angle = 90° corner which is all I'm using, I would enter 90.

Not using 'The number of sides'

Results:

End Angle = on a table or miter saw - set the miter at 35.264° or as close as possible.

Bevel Angle = on a table or miter saw tilt the blade at 30°

__________________________________________________________

Found this great calculator site on compound miters

This is great to calculate an 'L' or 'T' shaped house wing / floor plan.

I'm using the 1st calculator of Chris Glad's:

Slope = the pitch. I'm only using 45°, so I enter 45.

Included Angle = 90° corner which is all I'm using, I would enter 90.

Not using 'The number of sides'

Results:

End Angle = on a table or miter saw - set the miter at 35.264° or as close as possible.

Bevel Angle = on a table or miter saw tilt the blade at 30°

|

| Exterior view shows parts can slide together with very good mitered joints! |

|

| The interior view shows the ceilings coming together without any gaps! |

UPDATE

12 out 15 jigs DONE !! YAHOO !

Need to buy some maple, 3/8" & 3/16" dowels.

It won't be long now...

I found that the finger joints were rather difficult to separate - had to sand each one. I don't want to do that again, LOL.

_______________________________

_______________________________

...On the Verge of a Nervous Breakthrough...

All photos & images created by Mike's Miniatures on this blog are the property of Mike's Miniatures

You may copy them for personal use only

copyright 2012